Water-cooled plates are crucial components in modern thermal management systems, particularly for applications that require efficient heat dissipation. They are widely used in industries such as electronics, automotive, and aerospace, helping ensure reliable operation and extending equipment life by managing heat buildup effectively.

Key Factors Affecting Efficiency

1. Material: High thermal conductivity materials like copper enable rapid heat transfer.

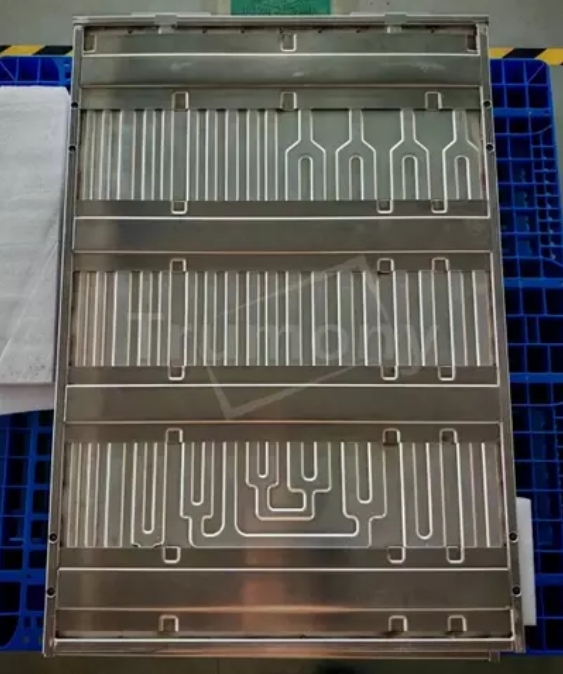

2. Channel Design: Optimized channel layouts, such as serpentine or parallel designs, maximize surface area contact, improving cooling performance.

3. Coolant Flow Rate: Controlled flow ensures uniform heat removal and prevents hotspots.

Advantages of Water-Cooled Plates

1. High Thermal Efficiency: Water-cooled plates offer superior heat dissipation compared to air-cooled systems.

2. Compact Design: They provide effective thermal management in smaller footprints, saving space.

3. Scalability: Customizable designs cater to specific application needs, making them versatile.

4. Reliability: Ensures stable operation even in demanding environments, enhancing long-term performance.

Why Water-Cooled Plates are Essential

Water-cooled plates are indispensable in thermal management, offering a high-performance solution for heat dissipation across various industries. With technological advancements in materials and designs, water-cooled plates will continue to evolve, maintaining their place as a cornerstone of efficient, reliable systems.